SCHEDULE

(Article 1)

text of approved code of

practice

The Code of Practice for the Protection

of Water

An approved code of practice under Article 16 of the Water Pollution (Jersey) Law 2000 (‘The Water Code’)

1 Foreword

This Code of Good Practice (generally referred to as ‘the Water

Code’) is issued as an Approved Code of Practice for the purposes of Article 16

of the Water Pollution (Jersey) Law

2000

(as Amended). Prior to issuing this Code, officers from Growth, Housing and Environment

have consulted with relevant Stakeholders, in accordance with Article 9 of

the Law.

The overriding purpose of the Code is to provide practical guidance

to those businesses that deal with fertilisers and promote good practices by

them, with the aim of preventing or reducing the pollution of controlled waters

(which includes in particular ponds, streams and reservoirs as well as all

groundwater).

Compliance with the Code will also constitute a defence of ‘due

diligence’ in circumstances that may otherwise amount to an offence under the

Law.

Accordingly,

I commend this Code to all concerned.

Deputy

John Young

Minister

for the Environment

31

January 2020

2 Introduction and

background to this water code

The purpose of this Code of Practice is

to provide practical guidance for those involved in activities that can have an

impact on water quality, including their advisors. The Code contains measures

to reduce the risk of causing water pollution.

2.1 Statutory

responsibilities and where to get advice

Businesses are strongly recommended to comply with this code of

practice, especially in view of the provisions of Articles 15(3), 18(4) and

18(5) of the Water Pollution (Jersey) Law 2000 which relates to a ‘defence’

under the Law of due diligence.

Natural Environment is responsible for administering the majority of

the environmental legislation highlighted in this Code and for the Water

Management Plan 2017-2021 (WMP).

To find out more about the Water Management Plan for Jersey and

about joint working to tackle these challenges please also contact the Natural

Environment.

|

Officers from Natural Environment can also offer advice

on practical steps that can be taken to minimize the pollution risks from

certain activities and on the requirements for Rural Support payments. You

can also seek advice from an independent consultant. Natural Environment

recommends that any advice taken is from a suitably qualified advisor, for

example FACTS or BASIS.

|

2.2 Useful Contacts

2.3 The

Water Pollution (Jersey) Law 2000

This Code of Good Practice for the Protection of Water (The Water

Code) is a Statutory Code under Article 16 of the Water Pollution (Jersey) Law 2000.

The Code applies to all landowners and users of land. These include,

but not limited to, farmers (arable and pastoral), small holders and liveries

and any persons disposing of wastes (such as treated sewage sludge, wastes from

water treatment, wood chip, other organic manures etc.) to land.

The Water Pollution (Jersey) Law 2000 contains pollution

prevention provisions and allows for the prosecution of people or organisations

who cause or knowingly permit the pollution of controlled waters. ‘Controlled

waters’ include all surface waters (such as ponds, streams, brooks, field

ditches) and groundwater.

Under Article 17(1) of the Water Pollution (Jersey) Law 2000, it is an offence to cause

or knowingly permit pollution of any ‘controlled waters’ unless it is done

under the conditions of a discharge permit.

|

Anyone wishing to discharge a polluting substance, or

energy, into controlled waters can apply to the Minister of the Environment

for a discharge permit which, if granted, will set out the conditions under

which that discharge can take place.

|

The maximum penalty for a pollution offence is an unlimited fine

and/or two years imprisonment. In addition, a person found guilty of causing

pollution may also have to pay for any remedial action and for costs incurred

by the Minister of the Environment.

Businesses can also be held liable for water pollution resulting

from tampering, vandalism or accidental damage by third parties.

2.4 The Water Management Plan

2017-2021 (WMP)

In 2014, the Natural Environment published the report ‘Challenges to

the Water Environment in Jersey’. The report sets out the then ‘current status’

of the water environment.

The Water Management Plan 2017-2021 (WMP) followed on from the first

report, setting out the actions that need to be taken as a priority to help

ensure healthy water supplies and better improve the status of the water

environment.

The key issues and objectives identified for the first five-year WMP

were:

· Nitrate: Reduce the concentrations in the Island’s groundwater and surface

water.

· Phosphates: Increase understanding of the likely scale of the phosphate issue

on the Island and require good practice measures to reduce soil phosphorus (P)

indices and losses of P to controlled waters.

· Pesticides:

Increase understanding of the levels of pesticides

in surface and groundwater throughout the Island whilst strengthening the

mechanisms that regulate, control and monitor pesticide use and screen for

hazardous substances.

By following the advice in this Code you will be making an important

contribution to achieving these objectives.

2.5 Water

Pollution (Water Management) (Jersey) Order 2020

In 2020, the Minister for the Environment designated eight Water

Management Areas (WMA’s) in Jersey under the Water Pollution (Water Management) (Jersey) Order 2020 to which this code of

practice is appended

The restrictions and requirements imposed by the new Water Pollution (Water Management) (Jersey) Order

2020

apply in respect of any person who imports, sells, purchases, stores or uses

any fertiliser in the course of a business

activity or operation in any Water Management Area designated by this Order. The

2020 Order provides:

Fertiliser in this context means ‘a chemical or natural substance

that is added to soil to improve its productivity’. This therefore includes

organic materials and manures used as fertilisers or soil conditioners as well

as inorganic (manufactured) fertiliser and other chemicals such as lime.

· Article 4 imposes requirements on the storage

of fertilisers.

· Article 5 imposes requirements on the

planning and management of fertiliser use, including a requirement for

producing a ‘nutrient management plan’ and an ‘organic fertiliser management

plan’.

· Article 6 requires equipment

for the application of fertiliser to be maintained in a good state of repair and in the case of mechanical

equipment for it to be calibrated at least once a year.

· Article 7 imposes restrictions on the

application of fertilisers.

· Article 8 is

concerned with soil cultivation and management.

· Article 9 sets

out the requirements for the keeping of plans and records.

|

The Water

Pollution (Water Management) (Jersey) Order 2020

There are restrictions and

requirements imposed by law that are designed to reduce the pollution of

water by some land management activities. See this Order for the current

legal requirements for the storage, planning, management and use of

fertilisers. This includes inorganic and organic fertiliser. There are also

rules in place for soil management and record keeping. Following the rules

are a legal requirement and you should ensure you know what they are and

whether they apply to you and your business activities and operations.

|

Note: This applies to all business activities or

operations except for any

amenity land or any landscape gardener working at domestic

premises.

For up to date information please visit www.gov.je and

type ‘water pollution’ into the search.

Land managers wishing

to receive States of Jersey financial support under the current Rural Economy

Strategy (RES) 2017-2021 must meet certain criteria to qualify for payment.

Applicants must demonstrate that they are operating to the standards required

by the RES and be able to provide evidence that all activities conform to all

relevant legislation and Codes of Good Practice (including this Water Code).

3 About Water Pollution

3.1 Sources of pollution

Water pollution can come from a number of different sources. If the

pollution comes from a single source, such as an oil or pesticide spill, it is

called ‘point-source pollution’. If

the pollution comes from many sources, it is called nonpoint-source or ‘diffuse

pollution’.

3.1.1 Point source pollution

A point source is a single, identifiable source of pollution, such as oil from a fuel

tank or slurry overflowing from a storage facility. Point sources of pollution

from agriculture may include discharges from animal housing and feeding

operations, slurry tanks, silage clamps and handling, mixing and cleaning areas

for pesticides, fertilisers and fuel stores.

3.1.2 Diffuse

source pollution

Diffuse pollution refers to those inputs and impacts which occur

over a wide area and are not easily attributed to a single source or incident. A

number of individually minor sources of contamination can be highly significant

over an entire water catchment. They are often associated with particular land

uses, as opposed to individual point source discharges. If the groundwater in a

catchment is contaminated, then any boreholes or wells and also the streams in

the catchment are also likely to be affected. Small water courses, with little

dilution as in Jersey, are more likely to be adversely affected by diffuse

pollution than larger rivers. Abstraction from watercourses can exacerbate this

problem by lessening the potential for dilution.

The impact of the agricultural industry, which covers approximately

50% of the land area of the Island is significant. The uncontrolled spreading

of slurries and manure, the application of inorganic fertilisers, the ploughing

and cultivation of the land and the use of pesticides can increase the risk of diffuse

water pollution. Run-off from roads and yards, the surface of fields, manure

and feed storage silos and storage buildings are also all potential sources of

pollution.

The causes of diffuse pollution can be difficult to remedy, mainly

because it is the collective impact of decisions made by many individual land

managers in respect of a number of different activities that make the

difference. Adhering to the good practice contained in this Code will help to

prevent damage to soils and losses of nutrients and promote good soil husbandry.

The activities in a catchment as a whole need to be considered and

solutions developed between stakeholders. Don’t hesitate to get involved in the

partnership initiatives being established in Jersey. By collectively taking

action to improve land management there is the potential to really make a

positive difference to water quality in Jersey and the environment in general.

3.2 Why is it important to

reduce pollutant losses to the environment?

The States of Jersey and many stakeholders have been working

together to protect the water environment in Jersey in recent years. Ongoing

monitoring shows that the quality of the Island’s water is improving but there

is still a lot to be done. Currently the majority of Jersey’s water bodies are

at ‘Moderate Status’. This needs improving as it

is less than ‘Good Status’ and is mostly driven by elevated levels of nutrients

found in both surface waters and groundwater. The long-term target is to

improve the environmental status of as many of our water bodies as possible to

‘Good Status’.

Excess nutrients, such as nitrogen and phosphorous, can harm soils,

watercourses, reservoirs and coastal waters, by causing algal blooms and by

changing the natural balance of plants, insects, and other life. In the wrong

place pesticides can kill insects and fish and can contaminate reservoirs

making the water unfit to drink. In some cases, there may be human health implications,

particularly from the effects of pesticides.

3.3 The

responsibilities of businesses

Many common practices pose a risk to water quality in Jersey. This

risk is increased where poor standards of management and operation are in

place. The inappropriate application of inorganic fertilisers, the storage and

inappropriate use of organic manures, the poor storage, use and disposal of

pesticides and the storage, leaks and spills of fuel oil can and do cause

pollution.

Make sure that you are informed about how to prevent water

pollution, that you manage and train your staff and contractors appropriately

and you are ready to respond to a pollution incident:

a. Land managers should ensure they have plans in place for the known

pollution hazards on their land in order to mitigate against a storage failure

or spill and to minimise the effects of an emergency on the water environment.

Carefully plan all storage, handling and use of

livestock slurries and manures, animal feedstuffs, silage effluent, fuel oil, dirty

water, fertilisers, veterinary medicines, pesticides and other chemicals and

ensure staff and contractors follow procedures. Don’t just leave plans on the

shelf gathering dust.

b. Staff and contractors who handle, store, use, spread or dispose

of any substance that could pollute water should be aware of their

responsibilities and know about the substances they are dealing with and the

effects they may have on the environment.

c. Make sure that all workers are suitably trained, qualified and

competent to carry out the operation for which they are employed. They should

know how to operate and maintain any equipment they use and know what to do in

an emergency.

d. Make sure workers are aware of the legal requirements and are

prepared to follow the guidance in this Code.

e. Know the position of boreholes, springs, wells, streams and field

and yard drainage systems and also which fields are prone to soil issues. Know

how to protect them during normal activities and in the event of a pollution

incident.

f. Make an assessment of the runoff risk from each field before and

during field operations. A field risk assessment map has been compiled and can

be accessed via www.gov.je to assist in making these

assessments. Also look at the weather forecast if appropriate.

g. Staff and contractors should also know about field drainage

systems and which fields are prone to soil erosion as substances, especially

phosphates and agrochemicals, can be attached to soil particles and carried

into water with the soil. Soil lost from the field is valuable topsoil that

cannot be replaced.

h. All areas and buildings should be designed and managed to

minimize runoff and pollution and staff should know the whereabouts of pipes,

channels and outfalls.

Inspect all storage facilities regularly for

leaks and damage.

i. Emergency contingency plans should be in the form of easy to

read documents placed in a conspicuous position and available to all staff in

case the land manager is not on the premises at the time of an accident. Those

involved should know where the contingency plans are located and be aware of

their content. Equipment required, should an emergency occur, must be easily

accessible and staff and contractors should receive regular training in its

use.

j. Ammonium nitrate fertiliser must be stored securely, where there

is no public access (and out of view from roads etc.). Ideally, store fertiliser

in a locked building, and carry out regular stock checks. Advice should be

sought from the Jersey Health and Safety Inspectorate (see Useful Contacts, Sect. 2.2).

k. All facilities and machinery involved in the storage and use of

the above substances should be regularly inspected to ensure they meet legal

and best practice standards.

|

Building Control Regulations are in operation to ensure

that buildings and storage facilities are built to the correct standard and

are fit for purpose. Pre‑application advice is available from the

Planning and Building Services.

|

4 Diffuse pollution

4.1 Diffuse pollution:

sources and pollutants

There is a wide range of potential diffuse pollution sources which

are associated with management practices and which can harm the environment.

This pollution tends to arise over a large area and is dependent on what

happens on the surface of the land and how it is managed.

Losses of nutrients or agrochemicals to land and water also

represent a financial loss to businesses. Businesses and the environment can

both benefit from applying these inputs in the right amounts and at the right

time.

4.1.1 Nutrients

Nutrients such as nitrogen (N) and phosphorus (P) can cause severe

problems in streams and coastal waters by, for instance, contributing to the

development of algal blooms or sea lettuce overgrowth on our coastline.

Nutrients can be lost from manures and slurries as well as from other organic

wastes spread on land, and significant losses can also be associated with

inorganic fertilisers and soil. Advice on their use must be tailored to the

particular circumstances that occur in Jersey in order to prevent losses and

reduce the risk of pollution.

|

When nutrients are carried out of the crop rooting zone

by water draining through the soil, they are said to have ‘leached’. This

represents a potential loss to the land owner and is a major cause of

elevated nitrate levels in our water in Jersey.

|

4.1.1.1 Nitrogen

Nitrogen occurs naturally in soil and water and is an essential

plant nutrient. Sources of organic and inorganic nitrogen are used to improve

soil fertility and promote crop growth. Chemical fertilisers (containing

nitrogen) usually contain nitrogen in the form of ammonium and nitrate. Nitrate

is very soluble and is therefore at risk of being washed into watercourses and

groundwater by leaching from the soil, especially in late autumn and early

winter when soil may be bare or there is little crop uptake. Subsequent

rainfall readily washes nitrate from the soil profile.

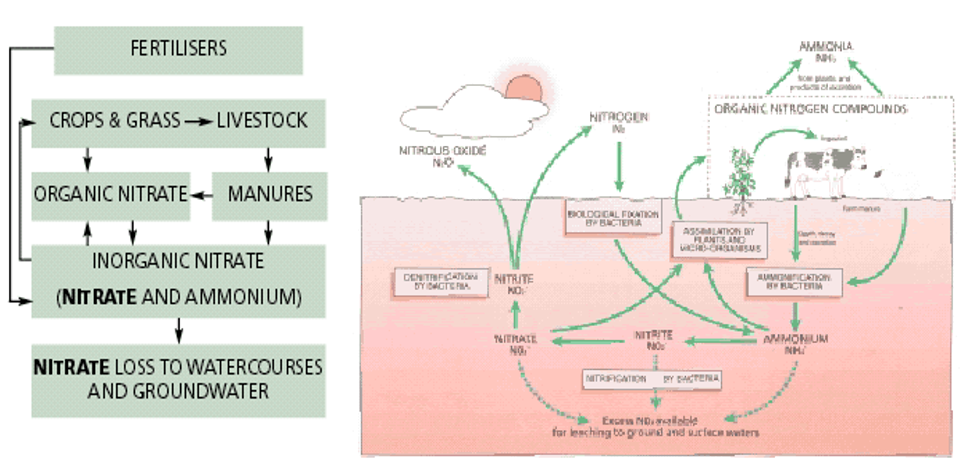

The main sources and losses of nitrate to water are shown in the

diagrams below:

Nitrogen based fertilisers are used in significant amounts in both

arable and livestock farming. Nitrate (from inorganic nitrogen fertilisers or

organic manures) is leached rapidly especially because it is very soluble. This

is particularly important during rainfall if nitrogen fertiliser has been

over-applied and the soils themselves are free draining. In areas where there

are sandy soils overlying a shallow water table, as in Jersey, there are

particular risks of nitrate leaching into groundwater.

There is also high risk of water pollution from nitrate losses if

livestock manures and slurries with a high proportion of their nitrogen content

in soluble form (e.g. slurry, pig and poultry manures) are applied when crop

uptake is low or non-existent (i.e. in the autumn or winter period).

Agricultural land is the main source of nitrate in many streams and

groundwater. This is a cause for concern for two main reasons. Firstly, because

of possible risks to human health posed by high levels of nitrate in public and

private drinking water sources. Secondly, elevated levels of nitrate and

phosphorus are considered to be significant contributors to eutrophication. (‘Eutrophication’

is the enrichment of water by nitrogen compounds, causing an accelerated growth

of algae and higher forms of plant life to produce an undesirable disturbance

to the balance of organisms present in the water and to the quality of the

water).

4.1.1.2 Phosphorus

Phosphorus is an essential plant nutrient that occurs naturally in

soils either as inorganic phosphate or as part of the organic matter.

Phosphorus fertilisers, manures and slurries supply phosphate to improve soil

fertility and to maintain plant growth. Once added to soils, phosphate is

normally strongly bound to soil particles and has a very low solubility.

Drainage water percolating through soils therefore normally contains very low

concentrations of phosphate, except when soil phosphate levels are excessively

high. Phosphate can also be lost from land if soil erosion occurs or due to

surface run-off following the application of manures and slurries.

Phosphorus can contribute to eutrophication of freshwater habitats

and is a particular threat to still or slow-moving freshwaters. Agricultural

and other land can be a significant source of phosphorus input to watercourses.

Phosphorus from land can reach watercourses in various forms and by

various routes. Their relative impact will depend on the particular catchment.

The main losses are:

· Surface run-off, particularly of

recently spread animal manures.

· Erosion of soil particles.

· Particulate and dissolved phosphorus in

water flowing from land drains.

· Phosphorus can also be leached to

groundwater.

4.1.2 Soil

Soil is considered a non-renewable resource due to the time it takes

to form. It should therefore be protected from damage and loss. In addition,

soil and water quality are very closely linked.

The quality of soil and its inherent fertility depends upon:

· The nutrient content and its balanced

supply to plants.

· Organic matter content.

· Soil pH.

· Biological activity.

· The physical condition of the soil (soil

structure).

Soil structure has a major influence on the rooting potential,

drainage, water-holding capacity, strength and consistency of soils. Any

degradation of structure will result in limited land use and agricultural

potential.

Eroded soil from grazed and cultivated land, muddy run-off from

roads, yards or field gateways can cause environmental problems such as silting

of gravel beds in watercourses. These areas are essential habitats for many

aquatic insects and provide spawning areas for fish and amphibians. Limit

livestock access to watercourses. Wherever possible, install water troughs and

fence off watercourses to eliminate this problem.

Soil particles are also important because they can carry more

serious pollutants. For example, some pesticides (such as pre-emergence

herbicides) bind firmly onto soil particles and are therefore liable to

contaminate watercourses when soil is lost from fields. Similarly, mud on yards

and roads may carry oily residues that can end up in a watercourse.

Phosphorus, attached to soil particles, can be lost from land via

run-off entering watercourses and cause pollution. It should also be remembered

that erosion very often involves the loss of topsoil, the most fertile soil in

a field.

The natural soil biological processes, which are vital for healthy

soils, are dependent on soil organisms ranging from bacteria and fungi to

earthworms. Soil management and the presence of contaminants affect the

activities of these organisms. Heavy metals, excessive fertiliser and organic

chemical loadings (including pesticides) can suppress such biological activity.

Good soil husbandry, nutrient planning and careful use of pesticides combined

with a well-managed crop rotation will maintain good biological activity.

4.1.3 Manures

and slurries

Livestock slurries and manures, and other organic materials can help

improve soil fertility and can save on manufactured fertiliser costs. However,

they are highly polluting if spread at the wrong time or in the wrong place and

can cause ‘point source’ pollution incidents and add to problems of diffuse

pollution through excess nutrient loadings to land. Apart from the nutrient

content and high organic loading, the possibility of microbiological

contamination can threaten streams, coastal waters and individual groundwater

sources and affect compliance with environmental quality standards.

4.1.4 Treatment

systems

Normally, the practices described in this section should be

sufficient to prevent or at least minimise the risk of diffuse pollution. In

some cases, however, it may be necessary to consider the installation of some

form of treatment system near the source of potential pollution. It may be

possible, for example, to install a wetland, reedbed or biofilter system to

deal with contaminated roof or dirty yard run-off at the farm. Specialist

advice should be sought on the selection, design and installation of such

systems and the Natural Environment should be consulted beforehand to ensure

that the requirements of environmental and waste management legislation will be

complied with.

4.1.5 Sewage

sludge and water treatment sludge

Sewage sludge or industrial wastes can contain potentially toxic

substances such as heavy metals and persistent organic chemicals which may

contaminate soil and pollute water.

Certain precautions prior to their use on land must be undertaken.

Analysis of the waste before it is used, assessing the lands suitability prior

to spreading, calculation of the growing crops nutrient requirements, soil

sampling and nutrient budgeting can all reduce the risk of diffuse pollution

occurring.

Anyone wishing to apply industrial wastes to land must possess a waste

management license unless the activity is exempt under the law (contact GHE).

Note that the application of sludge to land should comply with guidelines in ‘The

Safe Sludge Matrix’ and must be included in your nutrient management plan.

4.1.6 Compost

Compost can be made from a wide variety of biodegradable materials,

such as domestic garden (botanical) wastes or waste food. Some composting

systems also process small amounts of paper, card and untreated wood for

example. Composting can be defined as ‘the natural breakdown of

biodegradable materials through mixing, self-generated heating and aeration to

form a stable, soil-like material’.

There are a number of benefits of using compost as a soil

conditioner, as long as the compost is produced to an acceptable standard such

as PAS 100 or equivalent, which safeguards the environment and ensures the

product being applied is of a suitable quality.

Benefits of compost:

· Higher

yields - studies show that you can improve maximum

yield potential by increasing the amount of organic matter in the soil.

· Manufactured

fertiliser substitution - compost contains slow

release, crop-available nutrients, including phosphate, potash, magnesium and

sulphur.

· Better

soil structure and water management - adding

compost improves soil structure, which is good for crops (good water

infiltration and retention) and also makes it easier to work, saving fuel and

time.

· Inhibiting

pests and diseases - the organic action of compost

can help to inhibit pests and diseases within the soil (for example Rhizoctonia).

· Fuel

savings and traffic tolerance - compost improves

soil structure, making it easier to work whilst using less fuel. Improving soil

structure will make it more resistant to compaction from traffic and will

extend the conditions in which it can be worked.

4.1.7 Pesticides

and other chemicals

A very wide range of chemical compounds are used as pesticides and

each of these interacts with soil and water differently. Some will move through

soil quite easily and enter groundwater. Groundwater in Jersey is widely

extracted for both the public water supply and for private drinking water

(wells and boreholes).

|

Pesticides can have damaging effects on water habitats

and water resources, especially the Island’s reservoirs and groundwater. When

using pesticides, ensure you have sought qualified advice on the options

available in order to choose the right product and to safeguard against any

adverse effects on the environment.

|

Once present in groundwater, pesticides can be present for many

years and are very costly to remove. It is therefore important that such

chemicals are prevented from entering the island’s groundwater in the first

place.

The storage and use of pesticides is regulated by the Pesticides (Jersey) Law 1991. Pesticides should be used

in accordance with the Code of Practice for the Safe Use of Pesticides issued

under Article 7 of the Pesticides (Jersey) Law 1991. Please check for updates

with the Natural Environment as this legislation is currently being reviewed.

It is essential to avoid spraying pesticides in conditions and

circumstances where drift can occur. Buffer strips or unsprayed headlands

should be considered prior to spraying fields bordered by watercourses or

ditches.

If poorly managed or controlled, pesticides in tank washings, from

the cleaning of protective clothing, or from residues in bags or containers,

can cause pollution. Due to the particular risks that arise during pesticide

handling and wash-down operations, consideration should be given to the

installation of purpose-built facilities. Guidance on the design of such areas

is available from the Natural Environment or the Crop Protection Association

(CPA).

4.2 Effective planning,

management and control of potential pollutants

The key to minimising pollution is to ensure effective planning,

management and control of potential pollutants. Follow the advice in this code

and in the Water Pollution (Water Management) Order 2020 to help reduce the

impact of land management activities.

4.3 Rules on fertiliser

Nitrogen and phosphorus are key diffuse water pollutants and are

also major plant nutrients. By storing and using fertiliser appropriately you

can minimise pollution risks, comply with regulations and ensure that crops get

the nutrients that they need in the right amounts.

|

Applications of inorganic nitrogen to early potatoes are

subject to high levels of leaching. It has been estimated that up to 50% of

applied N is lost in this way. Put in financial terms this is worth £200,000

- £300,000 across the potato industry per annum.

|

The Water Pollution (Water Management) (Jersey) Order

2020

makes the following a legal requirement:

4.3.1 Storage

of fertilisers

a. Store fertiliser

where it can’t get into drains and watercourses or leach into groundwater.

b. Don’t

store fertiliser (inorganic or organic) within 50 metres of a borehole, well or

spring unless the storage is in a fit for purpose building or other structure.

c. Don’t

store fertiliser within 10 metres of any inland water (streams etc.), unless

the storage is in a fit for purpose building or other structure.

d. Don’t

store organic fertiliser in the same location for more than one year or use the

same location again for such storage for at least 2 years unless the

storage is in a fit for purpose building or other structure.

4.3.2 Make

and use a written Nutrient Management Plan that includes:

a. A field by field plan.

b. An assessment of the nutrient requirement of each planting or

crop.

c. An assessment of the nutrient supply from any organic fertiliser inputs.

d. A calculation of fertiliser to be applied taking into account all

other inputs.

e. A record of actual applications of fertiliser to each field.

4.3.3 Make

and use an Organic Fertiliser Management Plan that includes:

a. An assessment of the adequacy of storage based on production

figures and of whether there is sufficient land available for spreading.

b. The identification of suitable and unsuitable areas for the

application of organic fertilizer. A field risk map has been compiled to assist

with this and can be accessed via www.gov.je.

c. A risk assessment procedure for the spreading of organic manures.

4.3.4 Apply fertilisers (inorganic and organic) in

the right place, at the right time, in the right amounts and in the right

conditions:

a. Calibrate and maintain equipment at least annually.

b. Don’t apply more than the RB209 recommended amount of fertiliser to

any land.

c. Don’t apply more than 210 kg/Ha of Nitrogen to Jersey Royals.

d. Don’t apply Phosphate to soils with an index of more than 4, unless

evidence is provided that satisfies that, due to the low soil temperature, the

application of fertiliser with a P soil index in excess of 4 is necessary to

meet reasonable growing conditions;

e. Don’t apply fertiliser unless there is a demonstrated need and in

accordance with the advice of a properly qualified advisor. The amount of

phosphorus lost by erosion, leaching or drain flow will largely depend on the

soil phosphorus level. The higher the soil phosphorus levels, the greater the

potential loss.

f. Don’t apply more than 170kg/Ha of total nitrogen as organic

fertiliser as livestock manure to land or more than 250 kg/Ha total nitrogen in

all other cases in any 12 months.

4.3.5 Don’t

apply organic fertiliser to land that is:

a. Within 50 metres of a groundwater source.

b. Within 10 metres of any inland water.

c. Frozen, waterlogged, compacted on the surface or covered with

snow.

d. A loafing paddock[4] or other heavily-grazed field[5].

4.3.6 Don’t

apply manufactured fertiliser to land that is:

a. Within 5 metres of a groundwater source.

b. Within 5 metres of any inland water.

c. Frozen, waterlogged, compacted on the surface or covered with

snow.

4.3.7 Keep

accurate records:

a. Of fertilisers imported, sold or purchased and of their nature

and intended use.

b. Of the nature and composition of fertilisers stored, how long the

storage is for and how the storage is managed.

c. Of cropping and nutrient and pesticide applications.

Make the relevant records available to those sharing the land to an

extent that enables them to fulfil the requirements of this code.

4.4 Other measures to

consider that help reduce losses of nitrate

4.4.1.1 Avoid

ploughing up permanent pasture

Avoid ploughing up of traditionally permanent pastures, if possible,

due to the flush of nitrate which can continue for several years after such

action. If the permanent pasture is to be cropped or re-seeded, account should

be taken of the nitrate release in calculating the fertiliser applications for

the subsequent crop. If permanent pasture is to be re-seeded it is important to

ensure that a full crop cover is established as quickly as possible, by early

October at the latest.

4.4.1.2 Maximise

green cover

Winter crops sown in late October/November will have little effect

in reducing the amount of nitrate lost in the winter but can help to stop

surface runoff. A better strategy for reducing leaching is to grow a spring

sown crop (i.e. Jersey Royals) with the land remaining in grass or other catch

crop for as long as possible over the winter period.

If possible, a cover or catch crop, such as Italian Ryegrass or

mustard etc., should be sown in fields that would otherwise be bare over the

autumn and winter period.

Run-off from rutted or compacted ground can be a particular problem

for some rotations, including potatoes, maize and vegetables. The use of buffer

strips can assist in reducing the impacts of soil erosion and nutrient losses.

4.4.1.3 Grazing

Where intensive grazing is practised, a high percentage of the

nitrogen is returned to the land as excreta and urine resulting in high soil

concentrations of available N. The loss of nitrate from the grassland through

leaching may therefore be high, if intensively grazed by livestock throughout

the autumn.

4.4.1.4 Planning manufactured

fertiliser (containing nitrogen) application to grassland and arable crops

Manufactured fertiliser (containing nitrogen) should not be applied

to grassland until the spring, close to the time when the nitrogen is needed

for grass growth, and only then if soil and weather conditions are suitable. A

useful indicator to when nitrogen should be applied to grassland is the point

at which soil temperature is 5oC or more for five days. For arable

crops, manufactured fertiliser (containing nitrogen) should be applied at the

start of periods of rapid crop growth and nitrogen uptake.

4.4.1.5 Organic farming

Organic farming does still pose potential risks of nitrate leaching

due to organic manure use, grazing and ploughing-in of grass and crop residues.

Organic farmers should therefore follow Best Practice guidelines described in

this Code.

4.4.1.6 Using buffer zones near sensitive habitats or high risk areas

Leave, where possible, uncultivated strips of land adjoining

sensitive habitats (e.g. wetlands, botanically rich pastures, etc.). This area

can act as a buffer between the land under cultivation and the valuable

habitat. Take into account natural heritage and conservation issues.

Design of buffer strips will depend on local circumstances. The

detailed design of a buffer strip will be closely related to the problem to be

addressed, and specialist advice on the best way forward is recommended. A

small margin is still going to be better than none; however, if erosion

continues then consideration should be given to establishing a permanent grass

ley.

5 Soil Management

5.1 Soil

Management

Soil is a non-renewable resource (due to the time it takes to form)

and it should be protected from damage and loss. Taking the time to look at

soil structure is fundamental to achieving better land management, which

supports profitable farming and helps protect the environment.

Land should be managed in such a way that the risk of pollution to

controlled waters is minimised and managed in accordance with a ‘soil

protection plan’. This is to help ensure that the soil is managed, the

productivity of the land is optimised and the risk of pollution to controlled

waters is minimised.

5.2 Soil and water erosion

Soil erosion is a natural process, caused by the action of both wind

and water, though it can be exacerbated by inappropriate management. Certain

fields/soils are more susceptible to erosion than others and inappropriate

cropping, soil management and cultivations can increase the degree of risk.

Loss of soils through erosion can affect productivity and

profitability and result in off-site problems, including in water pollution,

flash flooding and road and drain blockage. Soil loss by water erosion occurs

from sloping arable and rotational grassland, particularly on sandy and loamy

soils. Water erosion may occur whenever rainfall intensity exceeds the

infiltration rate of the soil surface and the surface run-off is heavy and fast

enough to move soil particles. Bare soils, fine seedbeds, potato drills and ridges

are particularly at risk from water erosion.

Careful management can substantially reduce the risk of soil and

water erosion. The following measures may apply, and should be considered for

inclusion in the Soil Protection Plan, if required:

· Reduce run-off by increasing surface drainage

using sub-soilers to alleviate compaction.

· Encourage topsoil stability by using

organic manures.

· Avoid over-cultivation and excessively deep

working of the land.

· Soil erosion on susceptible fields can

be minimised by using minimum tillage systems, diversion systems and grass

buffer strips, and also by adapting field activities according to local risks

and previous experience of soil loss.

· Use minimal cultivation techniques with

the crop sown at right angles to the direction of rolling where applicable.

· Establish crops across the contours of a

sloping field.

· Avoid soil compaction by minimizing the

weight on each wheel and by spreading the load over as large an area as

possible by using dual and/or flotation tyres.

· The risk of run-off and losses of

nitrogen is increased in compacted soil. Physical damage to soils also reduces crop

growth and therefore the rate of nitrogen uptake by the crop. This damage can

to some extent be avoided by reducing the number of field operations

particularly when the soil is vulnerable to damage (e.g. when wet, after frost,

etc.). Flotation tyres can be both positive and negative, in that they limit

compaction but may encourage field access in conditions which are really not

suitable.

· Establish crops as early as possible.

· Cultivated soils which are light

textured should not be left without a crop or stubble cover during the autumn

and winter period. Changes to crop establishment and field management practices

should also be considered in fields with a history of soil erosion. Sow cover

crops early enough to establish cover over winter. Use permanent grass buffer

strips both within fields and between fields to reduce the potential impact on

watercourses.

· Sow permanent grass if repetitive water

erosion occurs which cannot be controlled by changes in husbandry or cropping.

· Avoid overgrazing and poaching on banks

of watercourses, particularly at watering points and feeding areas.

· Encourage regeneration of trees, shrubs

and vegetation which help to stabilize the borders adjacent to flowing water.

· When irrigating, ensure water

application is uniform and rates are not too high or droplets too large. This

will avoid sealing the soil surface and minimize run-off and soil erosion.

5.3 Soil

quality and nutrient status

Soils should be sampled and analysed at least every four years for

phosphorus, potassium, magnesium and pH. Soil sampling for SMN should be

carried out where appropriate.

Plants require adequate supplies of N, P, K, magnesium, calcium,

sulphur and trace elements to grow satisfactorily. These are generally supplied

from soil reserves, supplemented particularly for N, P and K by organic manures

and inorganic fertilisers.

If soil pH and organic matter are maintained at appropriate levels,

N, P, K and sulphur inputs and/or soil reserves can meet most plant nutrient

requirements. The appropriate type of lime should be applied to achieve the

correct balance between nutrients and target pH for crop or grass growth.

Excessive soil nutrient levels (particularly N and P) should be avoided as

leaching or erosion of nutrient rich soils to watercourses can cause pollution

and promote algal growth (i.e. eutrophication).

5.4 Acidification of soils

The majority of soils in Jersey are naturally acidic and are subject

to natural acidification processes from fertiliser and manure use, plant growth

and rainfall and to other pollutants from industry. Soil susceptibility depends

on soil type and cropping. The result is a reduction in the soil pH level over

time unless regular applications of an appropriate type of lime are made.

For most arable crops, the pH of mineral soils should be maintained

at pH 6.3. The reduction in lime application in Jersey is resulting in more

acid soils. This will reduce crop yield as well as the efficiency of manufactured

fertiliser use. Acidic soils will produce acidic drainage and may therefore

result in deterioration in water quality on the other hand. It is equally

important not to over-lime soils as this will reduce nutrient availability and

uptake of some trace elements resulting in reduced plant growth. The target is

to achieve the pH levels mentioned above.

5.5 The

importance of organic matter

Organic matter in the topsoil influences its physical, chemical and

biological behaviour, particularly its structural stability, ease of

cultivation, water retention capacity and nutrient availability to plants. Most

soils have a reasonable supply but if the organic matter in a soil falls, it

can impair its ability to support plant growth.

Where organic matter levels are lower than is desirable, they can

usually be increased by sowing a grass ley or by incorporating crop residues or

organic manures evenly over several years. The establishment of a cover crop

after Jersey Royal potatoes have been harvested can help maintain soil organic

matter levels and is also important to reduce soil erosion and reduce diffuse

pollution.

5.6 Creating

the best physical condition for soil

Over-compaction, due to damage caused by machinery and high stocking

densities, is an increasing problem in Jersey. Compaction restricts root growth

and limits soil drainage which in turn results in increased run-off, more

frequent flooding, increased erosion and the transfer of potential pollutants

to surface waters. In compacted soils, aeration is reduced resulting in poor

root growth and reduced availability of plant nutrients. To avoid the

degradation of soil structure, avoid the use of heavy machinery and livestock

poaching when soils are soft or saturated and select appropriate cultivation

techniques to mitigate against the creation of a ‘soil pan’ just below

cultivation depth.

Preventing compaction is easier than correcting it and regular soil

profile inspections should be made, particularly on headlands and tram-lines

and/or where Jersey Royals have been grown continuously for several years, to

assess soil conditions.

5.7 Restoring

disturbed soils

Prior to land being used for storage of building materials and/or

used for other development purposes permission must be gained from the Natural

Environment. In addition, the developer must provide a detailed inventory of

the quality of the land and the condition of both topsoil and subsoil and a

detailed specification and method statement for its reinstatement prior to the

work commencing. The degradation of agricultural land is an offence under the Protection of Agricultural Land (Jersey) Law 1964.

5.8 Protection

against the contamination of soils

To protect the long-term productivity of the soil in Jersey it is

necessary to be aware of the many potential sources of contamination, to assess

their significance and then take the necessary steps to prevent, limit or

remedy their effects.

Soil contamination may affect:

· Soil processes - (physical, chemical and

biological) leading to degradation of soil quality.

· Plant growth.

· Human or animal health, by uptake of

pesticides or Potentially Toxic Elements (PTEs) into plants resulting in entry

of toxins into the food chain.

· Watercourses by run off, leaching or

erosion from contaminated land.

Although a wide range of PTEs may contaminate soils, in practice

problems usually arise from a relatively small number of elements. The

following PTEs may cause problems due to the presence of excessive amounts in

soils: zinc, copper, lead, cadmium, arsenic, nickel, chromium, mercury,

selenium and molybdenum. While the presence of essential trace elements such as

zinc and copper is necessary for plant and animal nutrition, excessive concentrations

can affect the health of plants, animals and humans.

The most likely source of such PTEs is from the application of

sewage sludge and non-agricultural waste. Industrial organic chemicals, oils

and solvents and persistent pesticides can also contaminate soil.

The assessment of the suitability of a waste and the receiving soil

for disposal to land should take account of the:

· Waste degradation rates and the release

of nutrients and other substances during its breakdown.

· Chemical form of the element and its

likely interaction with the soil, given the pH values and the existing ‘background’

concentration of the element in the receiving soil.

· Effect of the element upon soil

organisms and processes.

· Timing of application.

· Effects upon plant growth.

· Possibility of uptake of potentially

harmful substance to edible parts of plants.

· Effects upon livestock, by consumption

of stored and conserved crops, grazing herbage or direct ingestion of

contaminated soil.

· Possible effects on the human food

chain.

Non-agricultural wastes should not be applied to agricultural land

unless they are beneficial to the soil or growing crop and should be applied

only when ground and weather conditions are suitable. All proposed applications

of non-agricultural wastes to agricultural land must be beneficial to

agriculture and meet the terms of the exemption in the Waste Management (Exemptions from

Licensing) (Jersey) Order 2006.

For full details see the ‘Non- Agricultural Wastes and other

Imported Organic Wastes’ section of This Code. It is also recommended that the

Sludge (Use in Agriculture) Regulations 1989 (as amended) and the Safe

Sludge Matrix 2001 is complied with if sewage sludge is to be applied to

agricultural land.

6 Storing and handling

livestock slurries, manures and other organic materials

6.1 About

livestock slurries, farmyard manure and other organic materials

|

There are

important health and safety issues attached to organic manures and slurries

and you should include the handling, storage and application of farm manures

within the farm's Control of Substances Hazardous to Health (‘COSHH’)

assessments. Further guidance is available in Health and Safety Executive publications.

|

Livestock

slurries, farmyard manure (‘FYM’) and other organic materials are valuable

sources of organic matter and major nutrients such as nitrogen (N), phosphorus

(P), potassium (K) and sulphur (S). They also contain magnesium (Mg) and trace

elements. Using these nutrients effectively can result in considerable savings

in manufactured fertiliser use.

However, these valuable nutrients can be lost from manures and

slurries during storage and spreading, posing a water pollution risk. When

slurry and other organic material gets into water very rapid and severe oxygen

depletion of the water can result, leading to fish and invertebrate deaths for

a considerable distance downstream. Manure and slurry can also cause microbiological

contamination of inland and coastal waters and groundwater, potentially causing

a breach of environmental quality standards.

6.2 Definitions and characteristics

It is important to bear in mind the following definitions as they

determine how the defined material can and must be treated and what materials

must be collected and contained.

Livestock slurry and manure are classified by the type of stock that

produces it and the physical characteristic of the slurry and manure.

6.2.1 Slurry

Slurry is excreta, including any liquid fraction, produced by

livestock whilst in a yard or building. It also includes any mixture consisting

wholly of or containing such excreta, bedding, feed residues, rainwater and

washings from a building or yard used by livestock, manure heap or manure storage

area, slatted building and/or weeping wall structures, or any combination of

these. Slurry has a consistency that allows it to be pumped or discharged by

gravity at any stage in the handling process. Slurry is defined as having a dry

matter (DM) content between 2% and 10%.

6.2.2 Solid

Manure

Solid Manure is excreta, bedding and feed residues produced by

livestock when kept in yards or buildings or manure with a high proportion of

straw in it from traditional bedded yards or solids from mechanically separated

slurry. Solid Manure is defined as having a dry matter (DM) content above 10%.

Manures can be in the form of solids, semi-solids or liquids. Solid manures can

be stacked but will produce effluent due to drainage and the leaching effect of

rainfall. Leachate from solid manures stored on yards or hard-standing will be

defined as slurry and must be collected and contained. Stores specially built

for solid manure will reduce the risk of pollution through run off and will

make it easier to handle and load.

6.2.3 Dirty

water

Dirty Water is any water containing washings from a milking parlour

or farm dairy. It also includes yard washings and rainwater runoff from open

hard standing areas that have been contaminated by manure, slurry or silage.

Dirty water is defined as having a dry matter (DM) content below 2%.

6.2.4 Pig

and Poultry manures

These contain high levels of nitrogen that can be readily available

and extra care is required to ensure the correct rates of application are used

when applying them to agricultural land to meet crop need and reduce the

potential impact of these manures and slurries on the environment. These

manures are also subject to the closed period (between 1st November and the

following 15th January in any year) in respect of applications to land.

6.2.5 Non-agricultural wastes and other organic

wastes

Wastes and materials such as sewage sludge, compost, seaweed, waste

vegetables (including potatoes) applied to land can be valuable sources of

nutrients and organic matter but are also subject to restrictions (see Non-agricultural wastes).

6.3 Temporary field storage

· Temporary field heaps of solid manure

should be placed close to where they will be spread, and in a position where

there is no risk of run off polluting water.

· Only manure that can be stacked and

remain in situ should be temporarily stored in field heaps.

· Do not place manure heaps within 10m of

a watercourse, ditch or field drain or within 50m of a spring, well or

borehole.

· Do not store organic fertiliser and other

organic material in field heaps in one place for any longer than 12 months. Do

not use the same location again for at least two years after that.

· Storing solid manure in a temporary

field heap must be in compliance with the Waste Management (Jersey) Law 2005.

6.4 Animal housing and associated Infrastructure, GHE

The type of livestock housing system affects the physical

characteristics of the manure or slurry. For instance, solid FYM is produced in

systems using straw or other bedding materials. Slurry is produced where

housing and feeding systems use little or no additional bedding materials, and

where excreta is scraped from solid floors or trodden into slats.

Some systems such as straw courts use a separate scraped feed area

to reduce straw use and these produce a combination of both FYM and slurry. All liquids produced from where livestock

are housed must be drained or scraped to a suitable collection system.

These liquids include drainage from passages and aprons used by livestock or

where slurry is scraped, contaminated wash water from milking parlours and

wash-down (dairy, pig and poultry buildings), and drainage from traditional

livestock boxes or straw yards.

6.4.1 Livestock

yards

Yards used for livestock, together with feed areas, will become

contaminated with slurry, bedding and feed residues. Whether these areas are

roofed or unroofed, they must be designed so that all contaminated drainage is

collected and contained.

Avoid large unroofed areas. It is also important from an economic

view that clean drainage from roofs and aprons is not allowed to enter the

slurry collection system in order to reduce the volume of slurry and dirty

water to be applied to land.

Drainage from feed areas is likely to be highly polluted and must

not be discharged to a watercourse. Although this material does not normally

contain manure or slurry, it can add to the volume of manure and slurry

collected.

Unroofed areas pose a high risk of pollution during periods of

rainfall. Where it is not feasible to direct and collect effluents into

existing storage facilities, a separate tank should be provided.

Tanks must always be appropriately sized, constructed and installed

with regard to the type of effluent being stored; and they must be properly

maintained at all times.

6.4.2 Parlours

and dairies

The drainage from milking parlours and the parlour pit must be drained

to storage tanks or the mains (if connected to the mains they require a trade

effluent consent from GHE Infrastructure). Washings from these areas will be

contaminated with milk residues, livestock excreta and cleaning chemicals. If

included in the slurry system, the volumes produced must be taken into account

in any calculation of the slurry storage capacity and land availability for

spreading.

There can be occasions when it becomes necessary to dispose of milk

produced on a particular farm to that farm’s fields. This can occur when bad

weather prevents collection of milk or if milk becomes contaminated

(antibiotics, chemicals, blood etc.) or colostrum has to be disposed of from

newly calved cows.

Ideally, waste milk may be fed to livestock, but it is advisable to

first consult a specialist advisor, especially where the milk is contaminated or

where large quantities are involved.

Milk is a highly polluting substance and should never be allowed to

enter a watercourse or reservoir. Waste milk should be diluted with water or

slurry before disposing to agricultural land. Dairy washings should be

collected and stored in suitable stores. As the act of mixing milk and slurry

may give rise to lethal or explosive gases, only small quantities of waste milk

should be disposed of to the slurry system.

BOD values of milk compared to other

on-farm wastes

|

|

Biochemical oxygen demand BOD (mg/litre)

|

|

Crude sewage

|

200 to 300

|

|

Dirty Water

|

1,000-5,000

|

|

Slurry

|

10,000-20,000

|

|

Silage effluent

|

30,000-80,000

|

|

Milk

|

140,000

|

Precautions should be taken before spreading contaminated milk on

grazing land and advice should be sought from Environmental Protection and the

States Vet. Milk should not be applied on land/sites with a high run-off risk.

The application rate should not exceed 50m3/ha (2000 gallons/vergée)

of diluted milk.

6.4.3 The

design and operation of slurry reception tanks and channels

Where possible, keep the distance between the animal housing and

slurry storage to a minimum. Slurry can be transferred from where it is

produced to the main storage tank either directly (via slats to storage tank)

or via a suitable reception tank or channel from where it can be pumped or flow

by gravity into the main tank. The system used will depend on the site,

relative levels, type of slurry and storage used.

Slurry tank capacity should include allowance for all excreta

produced by housed livestock for a minimum of four months, any washings, dirty

water run-off and rainfall and leachate from silage stores and manure heaps.

Good management is essential to prevent overflow. To reduce the risk

of overflow and ease operational management, a larger tank may be better. Tanks

should be sited to minimise pollution risk in the event of overflow: they must

be sited more than 10m from any inland or coastal waters and must be at least

50m from any spring, well or borehole.

A freeboard of at least 300mm must be maintained in all tanks (below

and above ground). Slurry should never be allowed to rise to rim levels as this

can cause catastrophic failure of the store.

The calculation of the minimum size for any slurry storage facility

must include provision for:

· All livestock excreta produced during

housed periods or at other times of the year (e.g. for dairy cattle).

· All other effluents directed to the

system including dairy wash water, contaminated yard areas and any silage

effluent.

· Rainfall and freeboard on the storage

tank(s).

6.4.4 The

design of slurry tanks

The design and installation must comply with the constructional

standards described by BS 5502 on Buildings and Structures for Agriculture

(Part 50). The base and walls of the slurry storage tank, any effluent tank,

channels and reception pits, and the walls of any pipes must be capable of

withstanding characteristic loads, shall be protected against corrosion and,

with proper maintenance, must have a working life of at least 20 years.

Where a channel or reception pit connects by pipe to another

container of lesser capacity which can overflow, two valves must be fitted in

the pipe to minimise the risk of overflow should a blockage occur preventing

closure of one valve. These valves must be kept locked when not in use and

should be spaced at least 1m apart to minimise the risk of both valves becoming

jammed open at the same time. Valves should be checked regularly and maintained

in full working order. All channels and reception pits must be covered or

fenced. Access openings for pumps and pipes should be guarded to prevent

accidents. Covers must be designed to carry the loads to which they will be

subjected. Access covers which can be easily opened or lifted should be kept

locked.

The design of any livestock storage system must take into account

rainfall that enters the system and contributes to the volume to be handled.

Both 'long term' and 'short term storm' rainfall events should be taken into

account, to ensure adequate storage provision. This is to ensure that land

application takes place when field conditions are suitable and the risk of

pollution from the operation is minimised. Conditions which will minimise

pollution risk also minimise field damage.

6.4.5 The

construction of slurry tanks

The contractor must be experienced in the use of concrete and other

materials used in the construction process. The relevant design requirements

are listed in the relevant sections in BS 5502, BS 8007 and BS 8110. When

considering substantially enlarging or reconstructing storage tanks, the

resulting structure must satisfy the above standards and receive planning

consent. It will therefore be essential to seek professional guidance prior to

making a commitment to any work.

6.4.6 The

management and operation of slurry systems

The person having custody or control of the management of any

facility for the handling and storage of livestock manures and slurries must

ensure:

· Good operational standards are adopted

(e.g. maintaining required freeboard).

· Maintenance is carried out to retain the

minimum performance requirements for at least 20 years (or the operational life

of the store).

The following operational actions should be carried out with all

systems:

· Check tank storage levels at a frequency

appropriate to its capacity, especially those receiving drainage from

contaminated yards or uncovered silos where rainfall can fill the tank very

quickly.

· Carry out regular spot checks at points

where leakage may occur, such as joints in pipework connected to pumps.

· Check that external drains are running

freely and are not contaminated.

· Check automatic pumping systems and

carry out routine maintenance. Pumping systems which can be removed from a tank

for inspection are most convenient and essential in situations where poisonous gasses

may be present.

· Check freeboard in tanks particularly

after periods of heavy rain.

· Check parts of systems which may freeze

during cold spells.

· Check tanks for the separation of

contents which may lead to the build-up of solids and loss of storage capacity.

Above ground tanks require regular attention where surface drying can cause

crust formation.

· Check all safety hatches after handling

operations. Empty and inspect all tanks (taking appropriate safety measures)

prior to animal housing.

· Persons having custody or control of

slurry are responsible for informing those individuals who act on their behalf

of the precautions to be taken to avoid overflow or spillage and the

consequences of causing pollution.

|

The Department of the Environment must be contacted in

the event of a pollution incident on its pollution report line tel: 709535.

All staff must be aware of the action to take in any emergency.

|

Appropriate training in the proper use of facilities and associated

equipment is essential. The dangers likely to be encountered from moving parts

on equipment and the presence of poisonous gases particularly from tanks within

buildings during mixing of slurry must be emphasised.

In slatted courts, livestock housed over the slats should be removed

and the building well ventilated prior to and during slurry agitation. If

possible, within buildings avoid the storage of silage effluent and slurry in

the same tank at the same time as this can increase the risk of poisonous

gases.

|

Harmful gases are generated at slurry stores and these

have been responsible for both human and animal deaths.

It is essential that controls for pumps be situated so

that they can be started and stopped without the operator entering buildings

which may contain harmful gases.

Stock or humans must not access buildings until

appropriate actions have been taken to prevent risk of harmful effects. Such

buildings should be well ventilated before entering.

If it is absolutely essential to enter an area which may

be contaminated by gas, operators should wear either an approved

self-contained or airline breathing apparatus. Full training must be given in

the use of this equipment before it is used. A notice should be erected at slurry

stores warning of the danger of poisonous gas and that stores should not be

entered without taking the recommended precautions.

|

6.4.7 The

maintenance of slurry tanks

Practical and safe methods must be employed to allow all facilities

to be inspected regularly for any signs of failure e.g. damage to surface

coatings on steel and concrete structures, damage and failure of store walls

and floor, leakage in pipes, connections and fittings.

The following is a suggested procedure which should be carried out

at least at annual intervals:

· Inspect walls and floors for cracking

and surface erosion. Only the exposed external surfaces of slurry tanks should

be inspected (see above).

· Inspect all drains and channels for

damage or deterioration.

· Check that all channels and pipes are

free flowing.

· Check all safety arrangements.

· List all repairs required and prepare a

timetable to execute the work. This may involve diverting slurry to other

storage or providing temporary arrangements.

Planning permission must be obtained with regard to any proposed

substantial enlargement or reconstruction.

6.4.8 Limiting

pathogenic micro-organisms in slurry and manures

Manures can contain pathogenic micro-organisms (e.g. E. coli O157, Salmonella, Listeria, Campylobacter, Cryptosporidium and Giardia)

which may cause food-borne illness. Factors such as the age, diet and

management of animals, as well as seasonal influences, affect the number of

micro-organisms in manures.

The management and handling of farm manures, particularly the length

of time they are stored, are important factors in the survival of

micro-organisms. The method and timing of manure applications to land can

affect the length of time that pathogens survive in the soil, and the

likelihood of them getting onto food crops. In order to reduce any risks of

food-borne illness resulting from the use of farm manures, there is a need for

due diligence.

To reduce the risk of transferring disease to healthy stock, pasture

should not be grazed for at least one month after spreading slurry or manure or

until all visible signs of the solids have disappeared.

Pathogenic micro-organisms usually die out over time. The rate at

which this happens depends on environmental conditions. In some conditions,

they can survive for several months following the spreading of farm manures or

deposition during grazing. They may also be present in dirty water, yard runoff

and leachates from stored manures.

Pathogens can be killed either in the manure itself or after

application to land. The main factors that will lead to a reduction in numbers

are:

· Temperature.

· Sunlight.

· Soil pH.

· Drying.

· Time.

· Soil microbes.

7 Organic fertiliser management

planning and application to land

7.1 Farm

manure and organic waste management planning

It is important to ensure that anyone who uses or plans to use fertiliser

on any land in Jersey as part of their business activities or operations

follows a written organic fertiliser management plan and nutrient management

plan unless they are exempted. This can be checked by reference to the Water Pollution (Water Management) (Jersey) Order 2020. Nutrient inputs to land

from organic materials need to be balanced with the inputs from inorganic fertilisers

and plant requirements.

7.1.1 The

resource value of organic materials

Livestock slurries and manures are a valuable resource. If correctly

applied, they can save money spent on inorganic fertilisers as well as

protecting the environment and adding organic matter to the soil. However,

because of this nutrient content they can also be polluting if not applied

correctly or accounted for in the nutrient management plan.

The nutrient value of manure or slurry should be estimated from

published data (RB209) or supported by representative sampling and analysis of

the manures and slurries from time to time. Dilution from rainfall, washings

and bedding materials must be taken into account.

|

Before agreeing to accept non-agriculturally derived

organic wastes, a farmer must carefully assess whether these additional

nutrient inputs can be utilised effectively to give a ‘benefit to agriculture

or ecological improvement’ without causing a pollution risk. Advice should be

obtained in writing from a FACTS qualified advisor or equivalent.

|

The DEFRA publication RB209 provides detailed information on the

nutrient requirements of crops and grass, as well as the nutrient value of

different types of manures and slurries and chemical fertilisers. Soil analysis

for pH, P, K and Mg must be carried out at least every 4 years to assess the

nutrient needs of the crops in the fields you are planning to apply organic

material or fertiliser to.

Livestock manures and slurries should be applied in amounts such

that the nutrient content, particularly of N and P, can be used by growing

crops. Excessive application rates can result in high N and P concentrations in

the soil and an increased risk of water pollution.

All applications of waste materials to soils should be in quantities

and at frequencies which convey positive benefits without causing pollution.

Advice, from a FACTS qualified advisor (or equivalent), should be sought on

what application rate is appropriate for each waste material, each soil and each

site.

7.2 Maximum application

rates of organic manures and slurries

Livestock manures and slurries are a valuable asset and should be

applied to agricultural land in accordance with the recommendations set out in

this section.

· The maximum application of livestock

manure to land must not exceed 170 Kg per hectare of total nitrogen in any

12-month period.

· The maximum application of organic

manures including non –agricultural

wastes and/or compost, to agricultural land must not exceed a total

nitrogen content of more than 250 Kg per

hectare of total nitrogen in any 12-month period.

· However, if the only organic fertiliser

to be applied is compost then the

compost may be applied in levels of up to 500kg of nitrogen per hectare over

any 24-month period as long as it –

a. Does not contain livestock manure;

b. Is applied as mulch or worked into the ground

c. Is produced to the British Standards Institute specification for

composted materials PAS100 or equivalent standard; and

d. The Minister has given written permission for the application.

· High readily available nitrogen manures

and slurries must not be applied to agricultural land during the closed period

(between 1st November and the following 15th of January in any year) except

with the written permission of the Minister.

· The amount and frequency of applications

should not be more than the nutrient requirements of the growing crop and take

account of the time of application and the residual value in the soil from the

previous application.

· The organic manures and slurry

application should be timed to minimise leaching.

· Any application of organic waste to

agricultural land must be included in an Organic Fertiliser Management Plan and

Nutrient Management Plan.

You must ensure the application of organic manures does not exceed

250 Kg per hectare of total nitrogen in any 12-month period of which only 170

Kg per hectare of total nitrogen may be from livestock manure (unless material

being applied to the land is compost only as specified above).

The table below, Surface application rates

in optimum conditions* shows the maximum surface application rates which

can be applied when soil and weather conditions are suitable to avoid run-off

and minimise the risk of pollution. The normal rate of slurry application is

generally between 25-30m3/ha (1000 – 1200 gallons/vergée).

7.2.1.1 Surface application rates in optimum conditions*

|

Material

|

Maximum

application rate†

|

Normal

application rates

|

|

Slurry

|

50

m3/ha (2000 gallon/vergée)

|

25-30

m3/ha (1000 – 1200 gallon/vergée)

|

|

Manure

(FYM)

|

50

tonne/ha (9 tonne/vergée)

|

30-50

tonne/ha (5.4 – 9 tonne/vergée)

|

|

Poultry

Manure

|

15

tonne/ha (2.7 tonne/vergée)

|

5

to 15 tonne/ha (0.9 – 2.7 tonne/vergée)

|

|

Dirty

Water

|

50

m 3/ha (2000 gallon/vergée)

|

25-30m3/ha

(1000 – 1200 gallon/vergée)

|

|

*Lower

rates should be used in the event of sub-optimum or difficult conditions and

may also be required to ensure that crop nutrient requirements are not

exceeded.